Blog

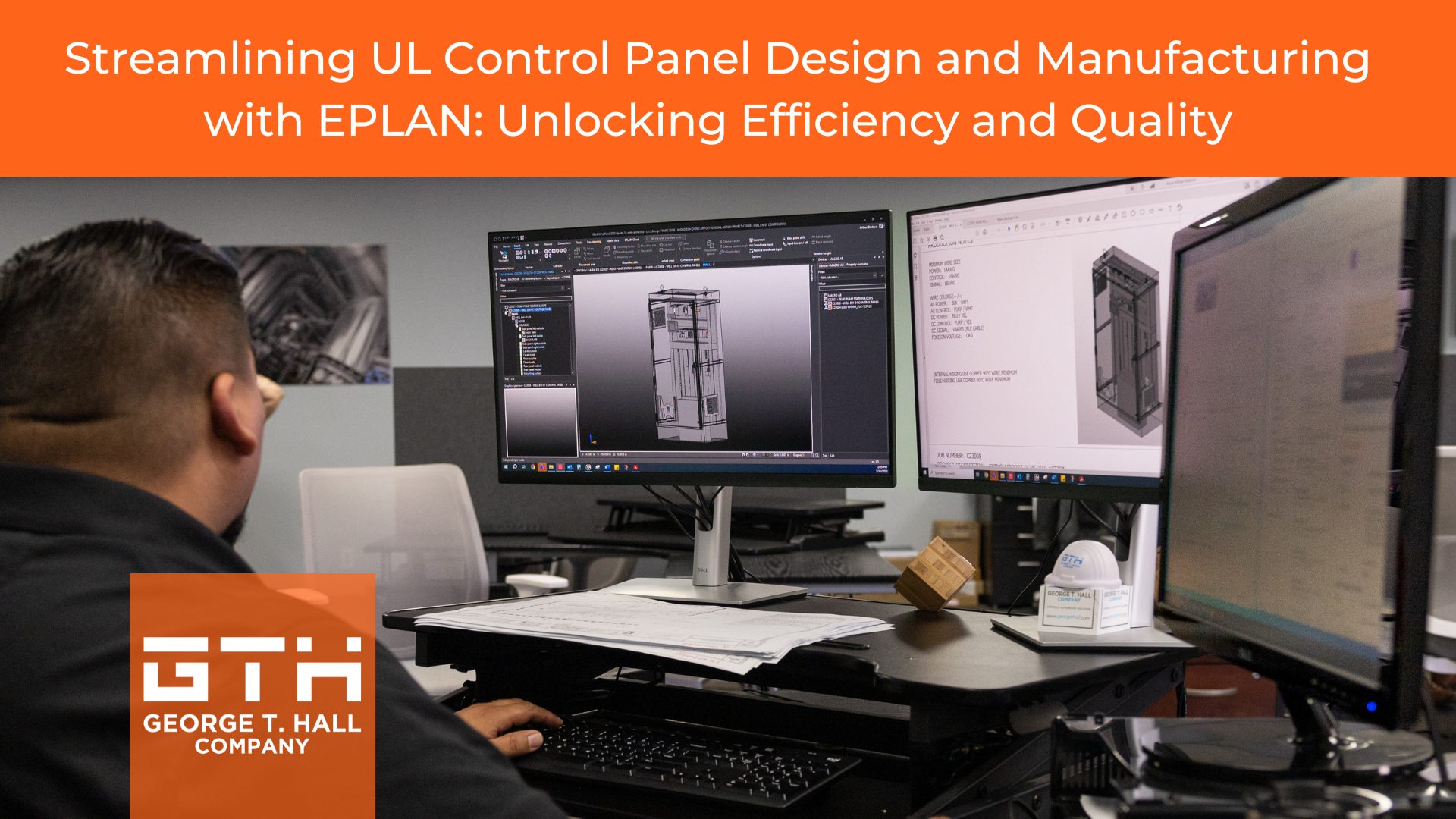

Streamlining UL Control Panel Design & Manufacturing with EPLAN: Unlocking efficiency and Quality

In today’s rapidly evolving world, efficient design and manufacturing processes are vital for successful control and automation solutions. GTH has chosen EPLAN as our software solution in achieving our efficiency and quality goals associated with control panel design. This software has been instrumental in achieving the goals of continuous improvement of our processes from design to manufacturing in our UL Certified Control Panel Shops. EPLAN offers numerous benefits to our processes of design engineering. In this blog we’ll highlight the advantages of using EPLAN and partnering with GTH for your control panel solutions.

With a century of experience, GTH brings expertise to automation challenges and creates sustainable, reliable control solutions. Our people and our solutions are built beyond expectations. Adding EPLAN and automating our design process was a natural fit for our long-term goals of continuous improvement. With its specialization for electrical engineering, comprehensive suite of modules, automation and standardization features along with the collaboration capabilities has created additional benefits to our process.

EPLAN stands out as specialized software tailored specific to our operation as it provides an extensive range of features and functionalities, designed to streamline the design and documentation processes for control panels. By focusing on the unique requirements of control panel fabrication, EPLAN enables our design engineers to work more efficiently and accurately, minimizing errors and reducing rework.

A comprehensive offering of various modules covers the entire lifecycle of control panel design. From initial schematics and layout planning to detailed documentation and production data, EPLAN ensures a seamless workflow for GTH’s team of design engineers. By integrating these functionalities into one software solution, EPLAN simplifies the design process and eliminates the need for multiple tools.

The automation capabilities of EPLAN significantly enhance efficiency and consistency in our control panel designs. The software automates time-consuming tasks such as device selection, wire numbering, and bill of materials generation. Additionally, EPLAN promotes standardization by allowing engineers to create templates, reusable macros, and standardized parts libraries. This ensures consistency across projects, reduces design times, and enhances documentation accuracy.

Effective collaboration is essential for successful control panel projects and with EPLAN we have been able to improve in the area of collaboration because of the features offered in the software. Multiple engineers have the capabilities to work on the same project simultaneously. Real-time collaboration, version control, and integrated change management ensure that all stakeholders are aligned and can work together seamlessly. This not only saves time but also enhances communication and reduces errors. With the add-on of eVIEW it allows structured collaboration both internally and externally. The eView feature allows for drawing markups to be made with defined steps throughout the design process. This cloud-based collaboration allows our engineers to redline drawings which can be reviewed by customers in the EPLAN platform where status is updated when they perform markups which can be immediately addressed, and the drawings edited.

With advanced visualization tools, including 3D cabinet modeling and virtual prototyping. These tools enable engineers to visualize the final product, identify potential design clashes, and optimize layout for efficient wiring and assembly. By detecting issues early in the design phase, EPLAN helps our engineers prevent costly errors during production, resulting in improved quality and reduced rework.

Partnering with GTH, a UL Control Panel manufacturer experienced in utilizing EPLAN, offers several advantages including compliance, design efficiency, documentation consistency, collaboration, and quality. UL compliance is critical for control panel manufacturers. As an experienced manufacturer of UL control panels, GTH ensures that the panels meet the stringent UL standards, reducing the risk of non-compliance issues. GTH’s Manager of the design Engineering team successfully completed the EPLAN certification program. With this knowledge he has created an internal training plan for each of our design engineers to ensure they have the knowledge and skills to utilize EPLAN to its fullest potential.

EPLAN has revolutionized the way we design and manufacture our control panels. It provides a specialized software solution that improves efficiency, consistency, and quality. By partnering with GTH you can reap the benefits of compliance, design efficiency, documentation consistency, collaboration, quality, and expertise. Embracing EPLAN and leveraging GTH expertise as control panel manufacturers is a powerful step in achieving excellence in your UL control panel solutions for your industrial operations.

Contact us today to learn more about our Expertise.

RELATED POSTS

George T. Hall (GTH) is proud to announce its new designation as Preferred System Integrator with ...

In the world of industrial and commercial applications, efficiency is paramount. To achieve optimal...

For nearly a century, George T. Hall Company has remained dedicated to delivering top-quality products...