Blog

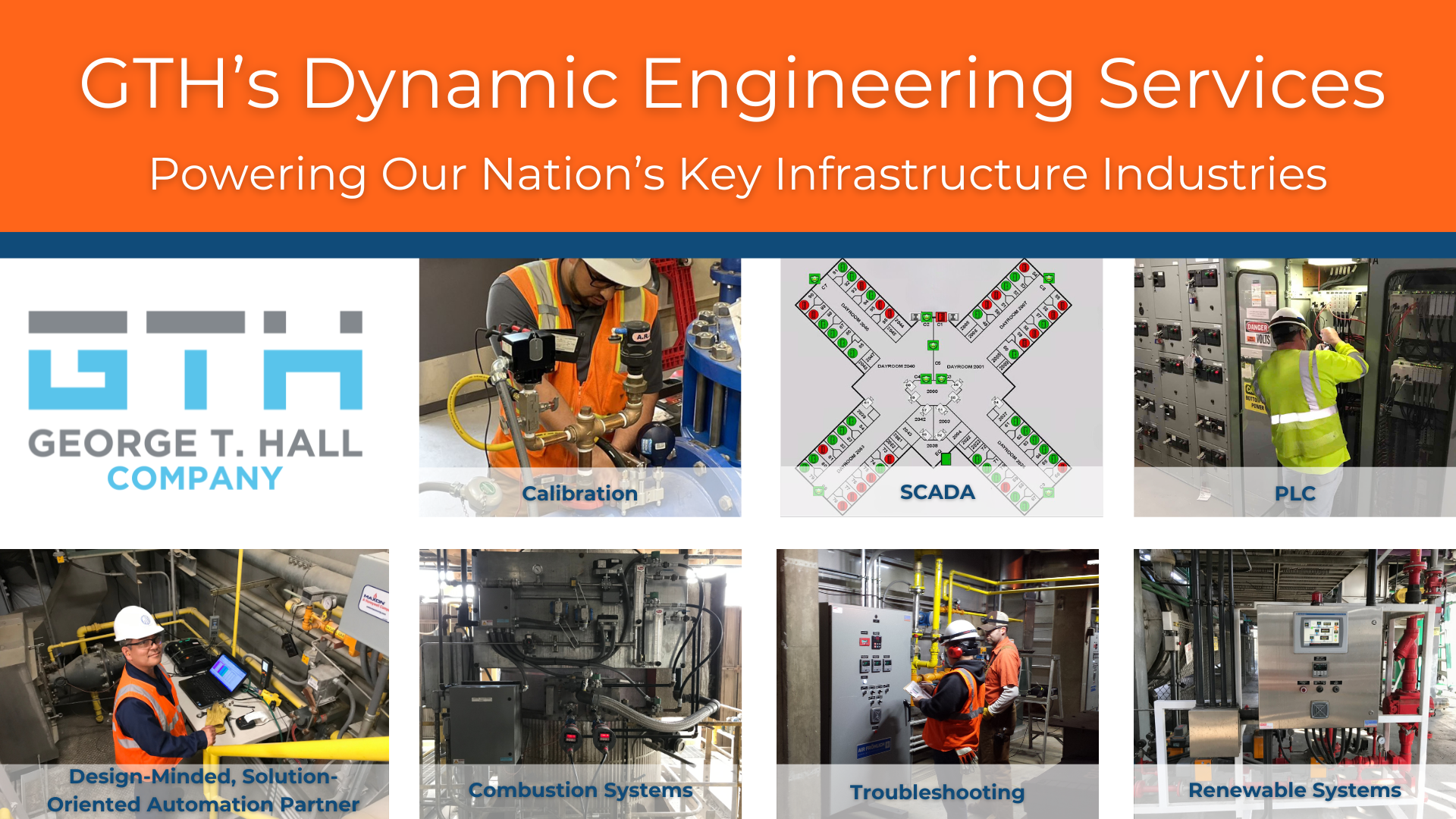

GTH's Dynamic Engineering Services: Powering Our Nation's Key Infrastructure Industries

Since the inception of the George T. Hall Company (GTH), our founder, George Hall coined the phrase "The House that Service Built" as a testament to our enduring dedication to customer service and technical support. Our continued growth as a company is driven by our passion for control and automation systems partnered with dedication to continuous improvement. As a full-service control solutions provider, we bring expertise and intuition across our nation’s key infrastructure industries in areas of system integration, combustion expertise, manufacturing expertise by delivering tailored manufactured solutions for OEMs as well as UL certified control panel fabrication, and industrial engineering services.

In this blog, we will highlight some of our key Engineering Services, which encompass field, remote, or in-house services to support the ongoing needs of your industrial operations. When control and automation challenges surpass your available resources, our engineers and technicians excel in a wide variety of engineering services. With experience in instrumentation, control systems, and software from the industry's leading manufacturers, and backed by ninety-one years in controls and automation, you can trust us to support past, current, and future technologies. Continue reading to discover more about our expertise in programming & configuration, calibration, and burner tuning.

Programming & Configuration Services

Programming is a core specialty at George T. Hall Company (GTH), encompassing PLC, SCADA, and HMI programming. Beyond these, our expertise extends to configuration for various devices such as video recorders, temperature controllers, wireless devices, combustion controls, and scaling for smart transmitters. At GTH, we maintain close collaborations with leading industry manufacturers ensuring up-to-date access to technical and application information. Click here to learn more about some of our featured partners.

Our proficiency is evident in the successful completion of numerous installations of data storage and retrieval software, such as Honeywell TrendServer, Wonderware Archestra and Historian, and ClearSCADA. GTH specializes in PLC, SCADA, and HMI programming, backed by certification and experience in system programming, making us an ideal CSIA (Control System Integrators Association) Certified System Integrator for handling complex control applications.

Calibration Services are a cornerstone of our commitment to meeting your process and quality requirements. Our skilled Field Engineers employ NIST-traceable instruments to conduct precise gas, temperature, pressure, and level calibrations on diverse instruments, including Chart/Video Recorders, Controllers, Gas Analyzers, and Temperature Sensors. Striving for excellence, we adhere to industry best practices and utilize ISA (International Society of Automation) data sheets when necessary. Our reliable calibration services encompass a range of instruments, addressing gas, temperature, pressure, and level calibrations. GTH ensures compliance with industry standards, reinforcing our dedication to quality and precision.

In addition to our Calibration Services, GTH provides efficient troubleshooting and repair services at our in-house service centers in Southern California and Northern Nevada. This approach guarantees swift turnaround times, friendly service, competitive rates, and a substantial one-year warranty on most instruments. With a focus on reliability and customer satisfaction, GTH is your trusted partner for comprehensive calibration, troubleshooting, and repair solutions.

Over the course of our 91 years in business we have developed the skills and expertise required for combustion and thermal control systems. One of the services we are well known for in this realm is burner tuning. Burner tuning refers to the process of adjusting and optimizing the combustion of fuel in a burner system to achieve efficient and reliable performance. It involves fine-tuning various parameters to ensure that the combustion process is balanced, producing the desired level of heat while minimizing issues such as incomplete combustion, excess emissions, or uneven heat distribution. The goal of burner tuning is to achieve efficient combustion, optimal flame characteristics, emission control, optimized heat transfer, prevention of continued issues and to meet air quality standards.

Adjustments are made to the air-fuel ratio to ensure that combustion is efficient. This helps maximize the utilization of fuel, reducing waste and operating costs. Burner tuning aims to achieve a stable and well-shaped flame. This includes adjusting the burner's air and fuel supply to create a flame that is evenly distributed, avoids impingement, and is appropriately sized for the application. Tuning helps control emissions, ensuring that the combustion process minimizes the release of pollutants such as carbon monoxide (CO), nitrogen oxides (NOx), and particulate matter. Burner tuning addresses issues such as flame impingement, flashback, or pulsation, which can lead to equipment damage, reduced efficiency, and safety hazards. Achieving the correct air-fuel mixture and flame characteristics enhances heat transfer efficiency, resulting in better overall performance of the combustion system.

Burner tuning is a crucial aspect of maintaining industrial burners used in various applications, including heating, power generation, and industrial processes. It is typically carried out by experienced technicians or combustion engineers who use specialized equipment to analyze combustion parameters and make adjustments accordingly. Regular burner tuning helps ensure that combustion systems operate at peak efficiency, reduce environmental impact, and extend the lifespan of equipment. Rest assured with our expertise, GTH, can support the tuning of your burner to ensure its continued use.

GTH is your Design-Minded, Solutions-Oriented Automation Partner

Automation and control systems are indispensable in today's industrial landscape, shaping the efficiency and service quality of key infrastructure industries such as water and wastewater facilities, pharmaceutical labs, mining operations, and food & beverage manufacturers, to name a few. Plant managers and/or engineers in these critical sectors seek partnerships with reliable System Integrators and Service companies, like GTH, to achieve excellence in automation and control systems. Partnering with GTH for onsite, remote, or in-house engineering services is a strategic decision that brings specialized expertise, efficiency, and ongoing support to industrial operations, contributing to the longevity and success of these key industrial operations.

As a beacon of expertise, George T. Hall Company offers a comprehensive suite of services to address the varied requirements of industrial processes in the nation’s key infrastructure industries. With a legacy in controls and automation spanning over 90 years, our engineering teams’ collective experience surpasses a century. We have continually evolved, embraced cutting-edge technologies and methodologies to ensure the seamless operation of your plant. By partnering with GTH to perform your engineering services it will allow you to direct your internal resources toward strategic initiatives and areas that contribute directly to your operations.

You can trust that our teams and our solutions are built beyond expectations. Contact us to learn more about our Engineering Services.

RELATED POSTS

Safety is paramount for all industrial operations; ensuring the well-being of personnel, protecting...

What is New in the Updated AMS2750F? The AMS2750 specification covers pyrometric requirements for...

The Watlow F4T with INTUITION temperature process controller has a wide range of field removable I/O...