Blog

Ensuring Safety, Speed, and Quality in Pharmaceutical Production

To ensure the quality and safety of medications, vaccines, vitamins, and other critical personal health products, pharmaceutical production facilities face some of the toughest regulations of any type of manufacturer. Beyond needing to comply with these regulations, like any manufacturer, pharmaceutical companies also need to operate their business efficiently. This means these manufacturers face the difficult balancing act between maintaining compliance and implementing good manufacturing processes that ensure lean and rapid production is possible. On the surface, these may seem like conflicting demands, but in reality, these needs can be met through the implementation of a well-designed control and automation solution.

Meeting Regulatory and Business Needs Through Automation, Repeatability, and Traceability

When automation is introduced to any production system, the possibility for human error at any step in the process is greatly reduced, inherently increasing the safety and quality of the end product. Automation also allows for repeatable processes that can occur more quickly, increasing production rates. However, as production speeds increase, there is a greater need to implement additional system safeguards that guarantee production accuracy. The risk of wasting a batch due to possible errors introduced when increasing production is not a risk pharmaceutical manufacturers can take on. At George T. Hall (GTH), we minimize this risk is by designing high-precision control systems that ensure process repeatability and provide tight tolerances on instrumentation for alarming. These systems help ensure consistency and dosing accuracy for the recipes used throughout manufacturing process.

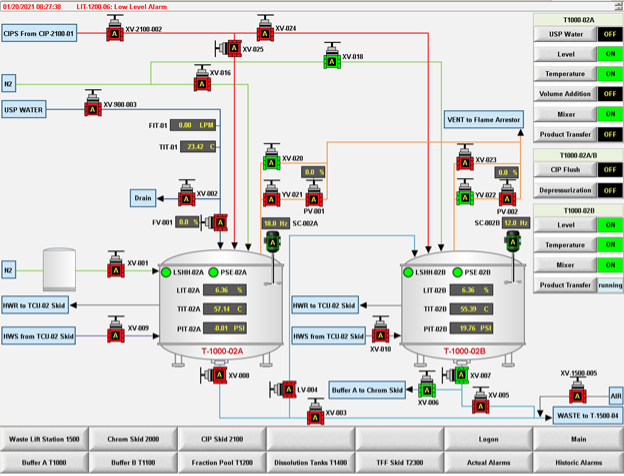

With an automated control system, recording, analyzing, and tracing production data is also much easier. For any manufacturer, especially one that is heavily regulated, the availability and traceability of data is key. Generally, when more operational data is available, operators are much more in tune with what is happening throughout the facility. Therefore, when we are involved in automation projects for pharmaceutical clients, we place a high priority on data collection and the availability of that data to operators. We want to be sure data from the programmable logic controller (PLC) in the field is rapidly transmitted back to the supervisory control and data acquisition (SCADA) system so that plant managers can see the health of their production system and make quick decisions. An example of a SCADA screen we developed for a pharmaceutical client is shown below.

In addition to meeting batch quality standards, easily available and traceable data also helps pharmaceutical manufacturers guarantee batch safety by adhering to regulatory requirements. This includes requirements such as the Food and Drug Administration’s (FDA’s) Code of Federal Regulations Title 11 which provides guidance on electronic documentation and signature. To make it even easier for manufacturers to comply with these types of regulations, the systems we design always come with extensive documentation and an intuitive documentation organization method. This helps manufacturers simplify documentation tracking and meet traceability requirements such as providing material certificates for each valve in a system. We believe documentation is a crucial, yet often overlooked, part of control and automation systems. If documentation is not managed effectively, pharmaceutical companies can quickly risk non-compliance, which can be costly.

Ensuring Quality and Safety While Working with an Accelerated Development Schedule

Sometimes the rapid development of certain pharmaceuticals is in the best interest of the public. For example, in 2020, to accelerate the development of the COVID-19 vaccine, the United States’ federal government provided a large amount of funding for vaccine development, manufacturing, and distribution through a public-private partnership known as “Operation Warp Speed” (OWS). As part of OWS, we partnered with a vaccine manufacturer to quickly develop the main control panel for automating their production system. As with most pharmaceutical operations, the sequencing and dosing accuracy of the required ingredients for this vaccine recipe was critical. Therefore, we developed a precision control system in a greatly reduced time frame of less than four months that offered a repeatable production process while still ensuring the safety, quality, and rapid production of the vaccine.

In short, at GTH, we are not only knowledgeable in developing precise control and automation systems for manufacturers in general, we also have a long heritage providing systems that can meet the strict quality and safety standards of the pharmaceutical industry. As a result, we can do what many integrators cannot. We help pharmaceutical companies meet the quality and safety standards of this highly regulated industry while still ensuring business needs, such as rapid and repeatable production with little waste or accelerated time to market, are met.

RELATED POSTS

Determining if your instrument is calibratable and when to consider an upgrade or replacement

In the rapidly evolving world of controls and automation, efficient design and manufacturing processes...