Pharmaceutical & Life Sciences

Control and automation solutions to enhance production safety, speed, and quality

PHARMACEUTICAL AND LIFE SCIENCES

To ensure the quality and safety of medications, vaccines, and a variety of life-saving medical devices and critical personal health products, pharmaceutical and medical device production facilities face some of the toughest regulations of any type of manufacturer. But, like any manufacturer, pharmaceutical and medical device companies also need to operate their businesses efficiently. At GTH, we are well-positioned to help manufacturers in these critical industries balance the demands of meeting stringent quality and safety standards with their business needs. We do this by developing control and automation solutions that enable lean and rapid production and integrating facility-wide PLC and SCADA solutions that enable reliability, repeatability, and traceability.

APPLICATIONS WE SERVE

![]() Pharmaceutical Process Control

Pharmaceutical Process Control

For seamless process control, we ensure your batch or continuous process control system seamlessly integrates with your facility’s essential systems such as sterilization, mixing and granulation, and tableting and tablet coating

![]() Medical Device Manufacturing

Medical Device Manufacturing

We are intimately familiar with the strict regulations medical device manufacturers are subject to and will ensure your instrumentation and software is setup to help you easily meet requirements such as FDA 21 CFR Part 11

![]() Automated Plant Utility Systems

Automated Plant Utility Systems

Our control and automation solution experience also covers essential equipment that is not directly part of the production process such as sterilization in place (SIP) systems and refrigeration and freezing units or rooms

AREAS OF EXPERTISE

UL Control Panel Development

As a full-service control panel provider, we design, engineer, assemble, wire, quality test, and start-up your panel to meet your exact specifications. At our two UL certified panel shops, we use only the highest quality UL listed components to ensure your system is designed to operate reliably across its anticipated lifetime. And, to be sure your critical manufacturing process will operate as intended from day one, we also offer comprehensive field startup services that consist of extensive system documentation, onsite I/O and loop checks, and thorough final start-up testing.

PLC & SCADA Programming and Integration

From implementing new production lines, to modernizing decades old operations, we have unmatched experience developing purpose-built, modern PLC and SCADA solutions for a variety of medical device and pharmaceutical production operations. Our solutions help these critical manufacturers minimize risk by providing process repeatability, tight tolerances on instrumentation for alarming, and traceability of key data needed to comply with various regulations. We have extensive experience with numerous hardware and software platforms and have earned certifications from many of the top PLC and SCADA manufacturers in the industry. With our platform-agnostic skill set, many decades of integration experience, and our well-established industry partnerships, we can develop and integrate PLC and SCADA solutions that will meet all your industry-specific control and automation needs.

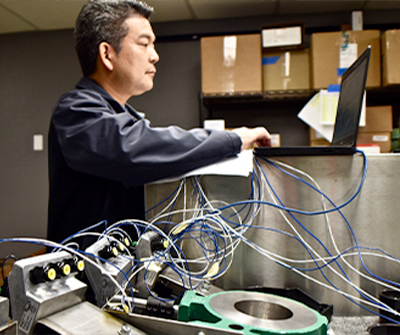

Instrument Calibration and Repair

Our field technicians and engineers will keep your systems running efficiently and reduce costly downtime through our wide range of onsite and in-house industrial services. For starters, we offer reliable calibration services using NIST-traceable instruments for gas, temperature, pressure, and level calibrations. When performing calibration services, we comply with industry best practices and utilize ISA data sheets when required. When precise calibration does not correct an issue, we offer in-house instrument troubleshooting and repair. Our service department offers quick turnaround times, friendly service, and competitive rates, as well as a one-year warranty on most instruments.

FEATURED PROJECTS

Automated Solvent Delivery System

See how GTH designed and implemented an automated solvent delivery that helped a manufacturer increase production capacity and repeatability while also improving safety at the facility.

Ensuring System Reliability For Large-Scale Coolers

Learn more about our partnership with Ace Coolers for developing custom ICPs that provide real-time visibility into operations, alarming, and system redundancy for continuous, reliable operation.

Corporate Headquarters

1605 E. Gene Autry Way

Anaheim, CA 92805

Ph: 714-939-7100

Manufacturing Headquarters

8565 Double R Blvd.

Reno, NV 89511-2270

Ph: 775-356-7401